Products >> CNC Plasma Cutting Machine >> Gantry CNC Plasma Cutting Machine

CNCSG-4000 CNC Plasma Cutting Machine

- Product No.:014

Our IntelliCut Gantries are annealed providing a long service life, extreme durability under heavy load and high duty cycle conditions. Gapless gearing transmissions allow for stable and smooth running at high speeds, so that we can achieve excellent cutting quality.

Integrated auto-ignition with automatic torch height controller, helps keep the optimum height between the cutting torch and the workpiece, so that we can achieve the best results.

Control and cut with several torches at the same time, improve your cutting efficiency whilst reducing maintenance costs. With a friendly operator interface, easy to learn, reliable, safe cnc systems, automatic programming, optimization nesting and piercing path, so that we can save steel effectively and reduce wastage.

CNCSG series CNC plasma and oxyfuel cutting machine is heavy duty, precision machine, specially designed for cutting large steel plate, can be equipped with multiple plasma torches and flame torches. It is very efficient, with excellent cutting quality.

Optional Function

- Powder marking device

- Straight line stripe cutting torch

- Straight line triple beveling torch

- Rotary triple flame curve beveling torch

- Rotary plasma curve beveling torch

- Blow and draft dust and fume collection system

- Water surface and underwater cutting table

Machine Features

- Gantry and box type welded structure, annealed, long service life, steady and durable under heavy load and high duty cycle condition.

- Gapless gearing transmit, stable and smooth running in high speed, so that we can achieve excellent cutting quality.

- Integrated auto-ignition with automatic height controller, keep the proper height between cutting torch and work piece, so that we can achieve the best cutting quality.

- Able to cut work piece with several torches at the same time, can improve cutting efficiency

- Low use and maintenance cost, dispensing special maintenance, friendly operator interface, easy to learn

- Reliable, safe cnc system, automatic programming, optimization nesting and piercing path, so that we can save steel effectively

Technical Data

| Effective Cutting Width (mm) | 2200 | 2700 | 3200 | 4200 | 5200 | 6200 | 7200 |

| Track Width (mm) | 3000 | 3500 | 4000 | 5000 | 6000 | 7000 | 8000 |

| Effective Cutting Length (m) | 2m less than track length | ||||||

| Cutting Thickness(mm) | Flame:5-120mm(Max 300mm) Plasma:1-80mm | ||||||

Basic Components

| Cutting Mode | Plasma and Oxy-Fuel/Flame |

| Drive Mode | AC Servo motor, Dual-drive |

| Cutting Torch Number | Between 1 and 7 |

| Driving Motor | Panasonic/Yaskawa |

| CNC Controller | Hypertherm EDGE CONNECT TC/EDGE CONNECT, LKNC-3200 |

| Available Plasma Power | Hypertherm, Kjellberg, Victor, ESAB |

| Programming Software | Fastcam, SmartNest, Hypertherm |

| Operation Language | Multiple |

Bevel Cutting Technology

X-definition Cutting Capability

CNC Drilling Attachments

SigmaNest Nesting Software

CNC Pipe Cutting

CNC Plasma and oxyfuel cutting machines are widely used for the industry of metal fabrication, shipping building, automation, Aerospace Military, Heavy Equipment, Pressure Vessels, Rail Transportation, Bridge Construction, Hardware Machinery, Energy Industry Etc.

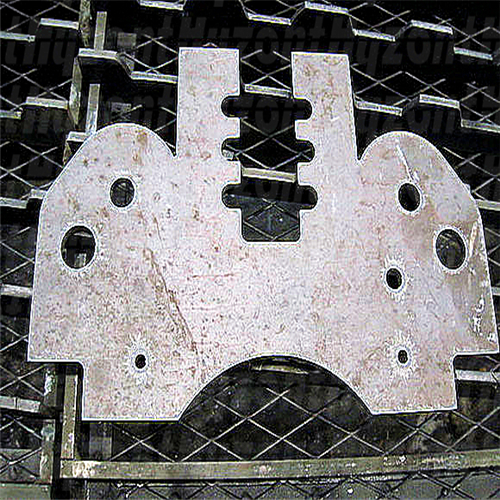

Cutting Sample

Products Category

Latest News

Contact Us

Name: Mr. Ricky

Tel: +86 13120953010

Mobile: +86-13120953010

E-mail: [email protected]

Skype: zgyricky

QQ: 2557281402

WeChat: zgyricky

Whatsapp: 0086 13120953010

Add: Block 1, No. 118 Hangtou Road, Pudong New Area, Shanghai

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online